The Järpen flow

INAB solved the complex logistics flow for hazardous waste

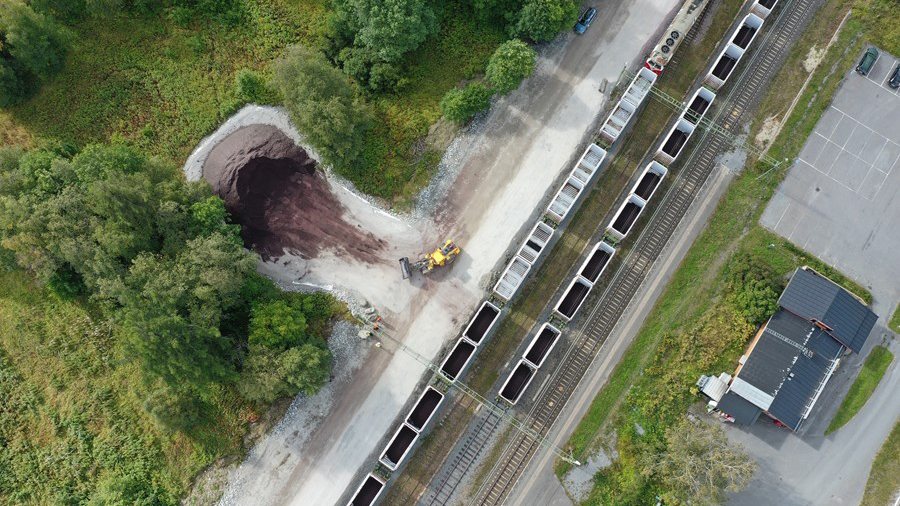

21,000 tonnes of contaminated soil from over 100 years of sulphite production, paper mills and wood grinding had to be transported from Järpen in Jämtland to the landfill centre in Umeå, Dåva DAC. This was also to be done by train, which had never been carried out on the same scale in Sweden before.

One aggravating factor was to try to create a smooth and cost-effective logistics chain where the railway becomes a competitive alternative to the lorry over a relatively short distance. The contaminated soil also needed to change modes of transport from rail to truck on the last leg from the Umeå freight yard to the landfill centre – while maintaining a train schedule.

Thanks to an extensive local and regional contact network, INAB could easily establish a close dialogue between the contractor RGS Nordic, Green Cargo, Innofreight, Frakttjänst in Umeå and Dåva DAC. This enabled a smooth process where we could get relevant competencies and actors involved at an early stage and build good cooperation. Our extensive expertise in these areas was a prerequisite for developing such a complex logistics flow.

iN BRIEF

Total transported volume in tonnes

21,000

Pollutant

Silica ash

Carbon dioxide savings (compared to lorry transport) kg

606,217

The environment is in focus when RGS Nordic manages the remediation project of Järpen’s industrial area in Åre.

Functional and flexible facilities

The project was successful, and we broke new ground! With skilled and driven project managers, courage and sharpness, the transport operation was carried out according to plan. An important detail that contributed to the success was the functionality and flexibility of our facilities. Umeå freight yard at Västerslätt in Umeå became the transhipment point for the contaminated soil. This, too, had not been done before.

The project was important and instructive internally for us at INAB and, in future, a new facility, Dåva Terminal, will specialise in this type of freight and pulp handling.

The project shows that it is quite possible to transport complex goods by train, even over shorter distances, and thereby reduce the climate footprint. This is an area we look forward to working with in order to meet the sustainability requirements of the future.

INABs role

“Our extensive network of contacts and our knowledge of how to put together logistics flows were strong contributary factors to the success of the project.”

– Daniel Rönnberg, former Market Strategist at INAB

Contact person

Aktuellt

Alla aktuella händelser-

Projektledarkompetens med inriktning på infrastruktur hjälper Umeå att växa

Det kommunala bolaget INAB-Infrastruktur i Umeå AB arbetar på uppdrag av Umeå, för Umeå och den regionala nyttan. Inom Umeå kommunkoncern pågår flera projekt där Inab har tilldelats projektledarrollen och nya projekt är på gång där Inab kommer att involveras.

Projektledarkompetens med inriktning på infrastruktur hjälper Umeå att växa

Det kommunala bolaget INAB-Infrastruktur i Umeå AB arbetar på uppdrag av Umeå, för Umeå och den regionala nyttan. Inom Umeå kommunkoncern pågår flera projekt där Inab har tilldelats projektledarrollen och nya projekt är på gång där Inab kommer att involveras.

-

Byggstart för Umeå hamns nya Energipir – en del i projekt Nordporten

Umeå Hamn AB har tecknat avtal med GRK för uppförandet av en ny Energipir, som är en del i en omfattande om- och utbyggnad av hamnen. Energipiren ingår i projekt Nordporten som inkluderar hela den inre hamnen. Arbetet påbörjas omgående och Energipiren planeras vara klar för drifttagning hösten 2027.

Byggstart för Umeå hamns nya Energipir – en del i projekt Nordporten

Umeå Hamn AB har tecknat avtal med GRK för uppförandet av en ny Energipir, som är en del i en omfattande om- och utbyggnad av hamnen. Energipiren ingår i projekt Nordporten som inkluderar hela den inre hamnen. Arbetet påbörjas omgående och Energipiren planeras vara klar för drifttagning hösten 2027.